PrimeSeal™

LifeSpan®

MaxProtect™

Shrink Bags for Processed Meats

EcoGuard™ |

Lightweighting

AmFiber™

AmFoil™

Plastic based

Designed with superior technology, Amcor shrink bags protect your bone-in and boneless processed meats throughout distribution while still letting the quality of your product show through at retail. Our wide variety of options guarantees the best fit for your product needs.

Applications

Food

Meat, Fish & Seafood

- Processed Meat & Poultry

Overview

Features

- Pre-made shrink bags designed to reliably conform to your product

- High shrink to minimize the material in the corners and your product purge

- Exceptional barrier to retain the maximum product shelf life

- Highlight your product quality with excellent optical properties

- Lower rework and waste with proven puncture resistance, designed for your product

- Seal through contamination and folds to reduce rework

- High end flexo graphics

- Select pigmented shrink bags available

- Available with optional carrying handles

- Available with optional EZ tear

Customer benefits

- ABP® high abuse shrink bags offer edge-to-edge boneguard protection. They eliminate uncovered bone punctures that can occur with patch bags and the resulting cost of rework in your operation. Up to 50% shrink.

- CBP® bone-in shrink bags offer excellent puncture resistance that reduces bone punctures and the resulting cost of rework. Up to 30% shrink.

- Clear-Tite® shrink bags for boneless processed meats deliver ultimate clarity, skintight fit and a multi-layer, abrasion-resistant structure.

- Pro-Tite® shrink bags for boneless processed meats give you all the advantages of Clear-Tite® bags with increased puncture resistance for the most demanding applications such as pastrami.

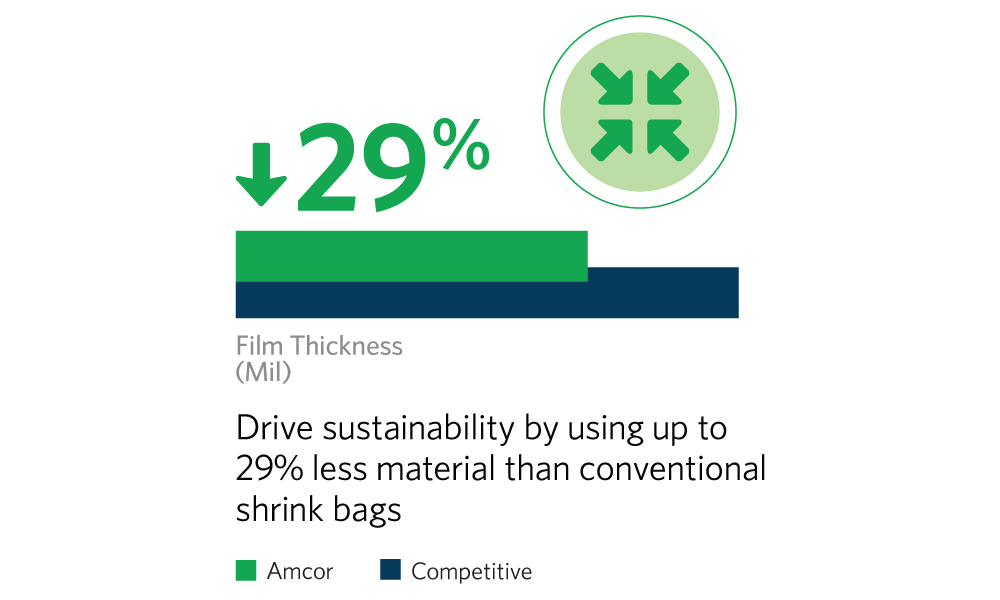

- Eco-Tite® recycle ready shrink bags for boneless processed meats are up to 29% thinner than conventional bags and do not contain chlorine, offering a more sustainable shrink bag option.

- Cook-Tite® shrink bags for whole muscle roast beef, molded hams and turkey breast ensure safe processing and distribution of your cooked products. Eliminate risk of contamination after processing with cook-and-ship bags.

- SPP shrink bags for surface post-pasteurized products improve food safety by withstanding immersion in 210°F water for up to 10 minutes and perform reliably on doublewire curved seal sealer/evacuators and conventional equipment.

- Eliminate the need for netting around large deli loaf products with Pro-Tite® Grab n Go handled shrink bags, saving packaging materials and labor in your production process.

- Add EZ tear for a clean and safe way to open meat products, eliminating the need for knives, improving safety and reducing risk of contamination.

End consumer benefits

- Superior product freshness

- Enhanced print quality for shelf appeal

- High gloss and clarity to see the quality of the product inside

- High puncture resistance prevents messy leaks

- Enhance consumer convenience with Pro-Tite® Grab n Go handled shrink bags - the convenient carrying handle provides an easy way to lift and carry deli loaf products up to 22lbs

- Give customers a clean and safe way to open meat products by adding EZ tear. The smooth directional tear eliminates the need for knives, improving safety and convenience.

Lightweighting

Lightweighting

Eco-Tite® shrink bags are up to 29% thinner than conventional bags.

Regions available

Latin America

Asia Pacific

North America

In the USA and Canada, call: 800-544-4672

Technical specification

Related content

Can be used with

Want to know more?

Tell us more so we can connect you with the right person for your request. Amcor Group GmbH respects your privacy and will only use your personal data to respond to your enquiry.

All fields marked with (*) are required.