What is Closed Loop Recycling?

Sustainability

November 14, 2019Reading time: 4 minutes

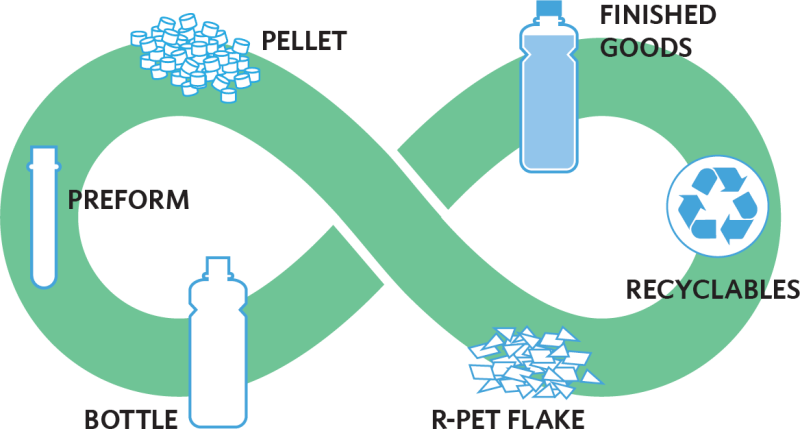

One of the goals within the plastics industry is to “close the loop,” which refers to the process of recycling and reusing products without material loss, thereby using fewer raw materials and reducing waste.

One of the goals within the plastics industry is to “close the loop,” which refers to the process of recycling and reusing products without material loss, thereby using fewer raw materials and reducing waste.

Recycling plays an important role, not only in reducing waste, but allowing more bottles, jars and other products to be made with recycled plastic. By now, most people have seen the “chasing arrows” symbol on products, which indicates that the product can be recycled. The symbol also denotes which type of material/recycling process is required. But, do you know what the symbol represents?

It’s a common misconception that the chasing arrows symbol, which was designed by a college sophomore in 1970, represents the three R’s (reduce, reuse and recycle). In reality, it symbolises the closed loop system, with each arrow depicting a step in the process:

1. Collection

The first step in a closed-loop recycling system is the collection of recyclable products, either from curb-side bins or drop-off centres. Once collected, the products are processed at recycling facilities and prepared to be sold to manufacturers.

2. Manufacturing

Creating new products from the recycled materials is the second step in the closed loop system. This might involve creating the same products (i.e., turning used plastic bottles into new plastic bottles, or manufacturing a completely different product (i.e., using recycled plastic to make polyester material for clothing items).

3. Purchasing

When consumers purchase recycled content products, they “close the loop,” which makes this third step very important to the process. Consumers must be willing to buy items made from recycled material.

What are the benefits of a closed loop system?

The process of recycling products that have reached the end of their life and turning them into new products has helped us significantly reduce the amount of waste we generate as a society. However, in order to close the loop, manufacturers must do more than simply recycle items they must use the recycled materials to make new products and consumers must be interested enough to purchase those products.

Many materials, such as plastic, can be recycled indefinitely (depending on the recycling method used), which means a product can potentially cycle through the loop repeatedly. In this way, the need for new or virgin materials is greatly diminished.

To illustrate, let’s look at how one type of plastic bottle is made. Polyethylene terephthalate (PET) was developed by chemists at DuPont in 1941, but it took until the 1970s for the PET bottle to become popular. It was the discovery of the blow molding method used today that led to the widespread use of PET bottles.

PET is a form of polyester, which is primarily derived from petroleum. Therefore, if we reduce the number of virgin PET bottles by using more recycled material, known as post-consumer resin (PCR), we also reduce our reliance on petroleum. It also takes less energy to make a bottle from recycled material compared to virgin materials.

“Closing the loop” not only helps to further reduce waste, but also benefits the environment by using less raw materials and reducing energy in the manufacturing process.

__Did you know that today’s vehicles contain, on average, 50% plastics by volume, but only 10% by weight? __

From the dashboard to the seats, plastic which is lightweight yet durable, is helping to improve fuel efficiency, and close the loop. An increasing number of auto parts are being made with recycled plastic. For example, the seat fabric for each Ford Focus is made with approximately 22 plastic water bottles.

Overall, the company uses more than 50 million pounds of post-consumer recycled plastics on the exterior of Ford vehicles made in North America. Other automotive manufacturers, including General Motors, Chrysler, Honda and Nissan are using similar amounts of recycled plastics in vehicle production.

What’s being done to close the loop?

Recycled PET bottles are closing the loop by becoming new PET bottles, which is why efforts to increase recycling are so important. In addition, every day, recycled plastics and other items are being used in new and innovative ways. For instance, asphalt has successfully been used to pave roads after blending the material with recycled plastics. Recycled plastics are also being used in the automotive and fashion industries, to name a few.

Additionally, our customers and partner organisations are working on initiatives to close the loop. Just recently, for instance, the American Beverage Association (ABA) announced a new initiative to get Every Bottle Back. This commitment includes investing in recycling infrastructures across the country, increasing awareness about the value of their 100% recyclable bottles (including the caps), and working with the World Wildlife Fund Resource: Plastic to reduce their plastic footprint.

The bottom line is when we recycle our used plastics, we help keep valuable materials out of landfills so they can live another life as other products. However, for the closed-loop recycling system to work, manufacturers, recyclers and consumers must work together to reclaim materials from our waste stream and use them to make new products that appeal to the consumer market.

To learn more about Amcor’s sustainable pledge and partner initiatives,

click here.

Sources:

“What does close the loop really mean,” by Mary Mazzoni, Earth 911, 2012. “Plastic Bottle Making Process,” by Robert Korpella, Sciencing.com, 2018. “Use of Recycle Plastics in Cars is Shifting into Overdrive,” Plastics Make it Possible, 2017.

President Amcor Rigid Packaging