Stelvin® Closure System – Wine Bottle Screw Caps

STELVIN® goes Greener

STELVIN® screw cap will now generate up to 35% less carbon emissions

STELVIN® screw cap will now generate up to 35% less carbon emissions

What makes STELVIN® Greener?

STELVIN® goes greener and reduces its carbon footprint by up to 35%* thanks to the collaboration with committed aluminium suppliers to set up an eco-responsible supply:

- Introduction of up to 46%** recycled aluminium in the manufacturing process

- Careful selection of low-carbon primary aluminum which is certified and independently verified***

*This reduction is based on the comparison with an aluminium screw cap made with a European average primary aluminium sheet (9 ton of C02/ton of production) (European aluminium, 2018)

** Based on supplier self-declaration according to ISO 14021

*** Level of specific GHG for our main aluminium suppliers are certified, others are in progress

Benefits of STELVIN® Greener

- Same product, same possibilities - Nothing changes in the look and feel, quality remains the same

- Lower carbon emission - a contribution towards reducing the environmental impact of wine packaging

- A recyclable solution - Screw cap is one of the most recyclable capping solutions, with 83% recyclability certified*

*According to Institut HTP Cyclos – in UK, EU, CH, NO

STELVIN® products

STELVIN® Benefits

Consistency and preservation of aromas

STELVIN® guarantees consistency from one bottle to another in preserving wine’s aroma, flavour and freshness.

No cork taint

Free from TCA (trichloroanisole).

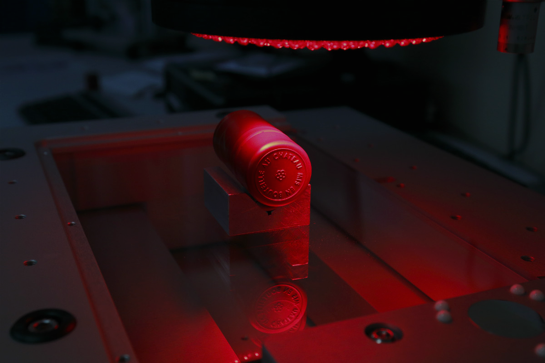

Various decoration options

STELVIN® closures can be decorated with intricate printing design options and embossing.

Easy to use

Easy to open, close, reopen, store and transport.

Easy to recycle

STELVIN® is recyclable. And by reducing the number of bottles affected by TCA, STELVIN® contributes to reducing the quantity of wine spoilage across the world.

STELVIN® Values

Innovation

In our different Research and Development centres, the teams of STELVIN® scientists and engineers work on developing solutions that are increasingly more intelligent, distinctive and respectful of our customers wines.

Their role encompasses several different facets: Product development, technical tests and research and validation.

Reliability

In order to guarantee constant and reliable supply, the production of our STELVIN® aluminium closures is fully integrated within the Amcor Group. From the aluminium foil to the decoration of the formed closure, we possess all the necessary expertise to create the perfect closure for your wine.

Sustainability

At Amcor, we constantly seek to reduce our environmental impact. During the STELVIN® ‘closures manufacturing process, we constantly endeavour to reduce our energy and water consumption, our production of waste and our overall carbon footprint. We use aluminium, an easily recyclable material.

And the good news is that in Europe the average rate of recycling of aluminium closure is 45% and that recycling only requires about 5% of the energy needed to make primary material.

Customer service

Our STELVIN® Customer Service teams are at your disposal to answer your technical and commercial questions. You will receive assistance when you start up your new capping line and also regular visits from our dedicated technicians. Finally, your STELVIN® sales representative can help you manage your closure stocks. At STELVIN®, our goal is your peace of mind.

Product quality

As your wine is your most precious asset, it deserves a closure of impeccable quality. All our production processes meet the appropriate food contact regulatory requirements and have received ISO9001 certification guaranteeing the consistent quality of our closures.

We manufacture according to world-class production standards and conduct annual internal audits (Amcor Manufacturing Excellence).

STELVIN® History

The STELVIN® adventure began in France in the 1960s, in the city of Chalon-sur-Saône in the heart of Burgundy. The first STELVIN® aluminium closure was developed in its final form in 1964 and the brand was officially registered in 1976.

They trust us: STELVIN® Testimonials

"We wanted to switch 9 of our 15 vintages to STELVIN®LUX closures for aesthetic and practical reasons. Since then, we've had lots of very positive feedback from our customers, particularly from wine bars and restaurants which appreciate how easy it is to open the STELVIN®LUX closures on our high-end LePlan-Vermeersch RS and GT wines. STELVIN®LUX is ideal for our customers who offer wine by the glass."

Ann Vermeersch, Winemaker, Vermeersch family, Rhône Valley, France

"We pride ourselves from our vineyards to the winery, to the wines we put in the bottle. We want to over deliver on the bottle the consumer takes home. By using the STELVIN® LUX on all our 11 McManis wines, we are achieving that. STELVIN® is one in its self when it comes to screwcaps. The partnership between Amcor and McManis Family Vineyards is strong and I see signs of it growing year after year."

Justin McManis, McManis Family Vineyards, California, USA

Follow STELVIN®