Launch Preparations for a New Market Disrupting Packaging Material System

Pharma

July 26, 2022Reading time: 3 minutes

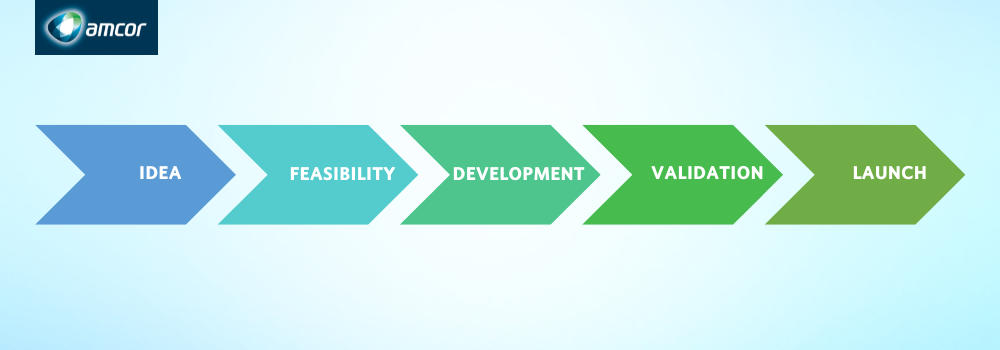

In this blog, Ed Haedt, Amcor’s Business Development Director of Healthcare North America discusses the importance of checking all the boxes when taking a new product from concept to commercialization.

In this blog, Ed Haedt, Amcor’s Business Development Director of Healthcare North America discusses the importance of checking all the boxes when taking a new product from concept to commercialization.

An important step in the process of bringing a new disruptive packaging material from concept to commercialization is to understand how key stakeholders and end-users perceive the value of the innovation. Almost by definition, market disruptive packaging innovations will require stakeholders to consider something new and accept something different to bring step-change value to their targeted customers. This makes it critical to help stakeholders work through the change and understand how it will impact their processes. Does it reduce or increase productivity? Does it add extra work or simplify the process? Does it increase or decrease waste? Is the waste recyclable or not recyclable? Does it require new equipment, changes to existing equipment or just drop into existing equipment? Do intended customers need to learn a new way to use or open the package? How do customers perceive the innovation versus incumbent packages? These and other questions need to be answered as positively as possible before the intended value-added feature(s) can be fully appreciated.

New sustainable packaging solutions often come with at least some minor differences from existing packaging. Less sustainable, incumbent, multi-material packaging films have been optimized over many decades both in the material formulation and the equipment that processes the materials into packaging. To successfully launch a completely new sustainable, lower carbon footprint packaging solution, the differences and comprises must be minimal. Amcor has successfully brought many no-compromise sustainable packaging solutions to the market in recent years. The following is an example that illustrates a go-to-market approach for its recycle-ready blister packaging solution.

Amcor HealthCare™ AmSky™ Blister System

Amcor’s AmSky™ Blister System is an excellent case study to illustrate how it engages stakeholders, addresses their questions, and gains their confidence that end customers will be rewarded with at least the same or a better user experience while achieving substantial improvements in sustainability. Amcor used the following approach to overcome stakeholder skepticism about its groundbreaking new pharmaceutical blister packaging solution:

1. Packaging Machine Manufacturer Trials

Amcor confirmed a wide operating window on existing packaging equipment supplied by various leading equipment manufacturers. Their endorsements provide pharmaceutical manufacturers confidence the AmSky™ Blister System solution will work on their existing machines.

2. Third Party Subject Matter Expert Evaluations

Rigorous assessment by 3rd party subject matter experts at Montesino provided an unbiased confirmation that the AmSky™ Blister System meets technical, processing, consumer, and regulatory requirements for pharmaceutical packaging.

3. Consumer Panels

Amcor obtained consumer insights directly from end-user panels simulating the targeted blister packaging customer base. Amcor’s state-of-the-art Innovation Center is an immersive customer experience facility with experts trained to assess consumer insights that correlate to real world customers.

4. Claim Substantiation

Amcor’s recycle-ready claims were substantiated by following prescribed guidance testing and obtaining certifications by the leading recyclability governance organizations.

5. Manufacturing Support Capability

Trained a team of field service experts to support packaging machine trials and qualifications of the new packaging material system.

The steps above helped us with the following:

-

Gain the confidence that very minimal process parameter changes would allow the AmSky™ Blister System to be utilized on standard blister machines and tooling.

-

Learn that end-users preferred the look, feel, and usability of AmSky™ Blister System versus traditional PVC/Foil blister packaging.

-

Build a technical customer support team with the capability to work through qualifications, speed conversion and troubleshoot any manufacturing challenges related to this innovative sustainable packaging solution. This support has been found to be critical given the many technical requirements for pharmaceutical packaging, including materials, processability, and end-user expectations. It has enabled Amcor customers to focus more time and effort on developing their own go-to-market strategy and quickly qualifying this market disrupting, sustainable packaging solution for their pharmaceutical and nutraceutical customers.

Learn more about how Amcor provides customer support from concept to commercialization, including design, prototyping, barrier testing, package property modeling, packaging for stability testing, machine trial support, and more.

Join Amcor's Research and Development Team for a one-hour session discussing strategies to expedite new product development in the pharmaceutical packaging industry.

Related Insights

Improving Sustainability Scores of Pharmaceutical Packaging

June 16, 2022

Pharmaceutical companies have a heightened interest in sustainable practices. Some of the largest pharma companies in the industry have recently committed to sustainability goals regarding emissions, with most companies focusing on carbon footprint.

Pharmaceutical companies have a heightened interest in sustainable practices. Some of the largest pharma companies in the industry have recently committed to sustainability goals regarding emissions, with most companies focusing on carbon footprint.

Sustainability trends impacting the pharmaceutical packaging industry

May 19, 2022

The pharmaceutical industry, healthcare providers and patients are all increasingly aware of the need for more sustainable packaging. This means a growing demand for more sustainable solutions while ensuring the quality and safety requirements that are fundamental when designing pharmaceutical packaging.

The pharmaceutical industry, healthcare providers and patients are all increasingly aware of the need for more sustainable packaging. This means a growing demand for more sustainable solutions while ensuring the quality and safety requirements that are fundamental when designing pharmaceutical packaging.

Amcor develops breakthrough recyclable healthcare packaging

April 29, 2021

Building on our recent track record of breakthrough innovations to deliver recyclable packaging, Amcor is today announcing customer trials of the world’s first recyclable Polyethylene-based thermoform blister packaging, AmSky™.

Building on our recent track record of breakthrough innovations to deliver recyclable packaging, Amcor is today announcing customer trials of the world’s first recyclable Polyethylene-based thermoform blister packaging, AmSky™.