Chemical recycling for flexible plastic packaging in Europe

Sustainability

February 15, 2023Reading time: 4 minutes

What is chemical (or advanced) recycling? And what opportunities does this emerging process present for flexible packaging? We'll take a focused look at Europe.

What is chemical (or advanced) recycling? And what opportunities does this emerging process present for flexible packaging? We'll take a focused look at Europe.

Article updated: April 2024

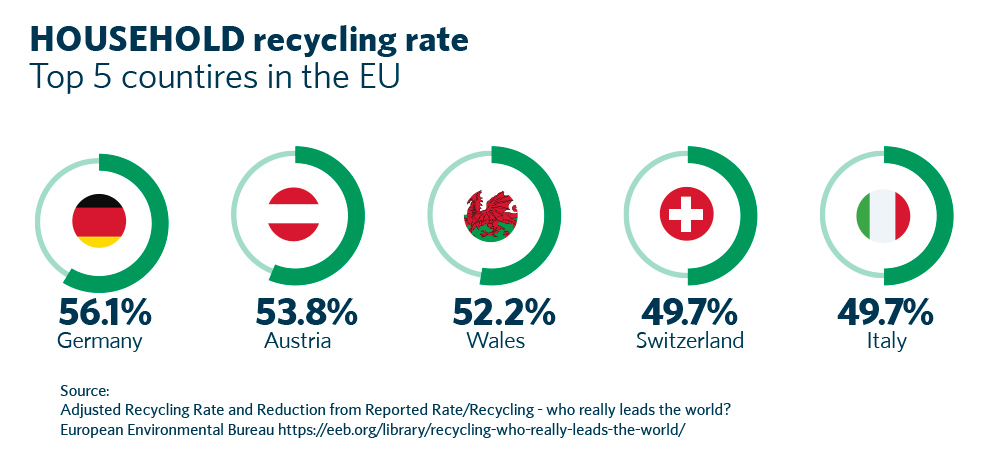

EU member states have some of the most advanced recycling systems in the world and the highest collection rate for household waste. A joint study from European Environmental Bureau and Eunomia (1) states that Germany’s household recycling rate is the highest of the world, achieving a rate of 56.1%.

Some types of plastic packaging already function well in large scale collection and recycling systems, for example, PET bottles. One of the most sophisticated recycling systems today is mechanical recycling of PET bottles. When properly collected and recycled, used PET bottles can become new PET bottles, as well as other products like textiles.

With mechanical recycling, flexible plastic packaging (e.g. wrappers, bags and pouches) are generally recycled into different applications, such as construction materials, automotive components, garden pots, furniture and more. However, some new flexible packaging (e.g. for non-food applications) can be produced from this mechanically recycled material.

Governments and policymakers are promoting a circular economy for plastic packaging with new regulations. Recycling targets set by the proposed European Packaging and Packaging Waste Regulation (PPWR) state packaging must be recycled at scale, with a 55% recycling rate by 2035 for all packaging categories, including flexibles.

In addition, a new method for measuring the recycling rate in which losses along the process are taken into account makes this an even more ambitious target (2). In 2018 in Europe, 81% of plastic packaging waste was collected and 41% was effectively recycled (3), so there is still some way to go.

Is chemical (or “advanced”) recycling the solution to improve flexible packaging recycling?

In order to meet EU recycling targets and initiatives promoting the use of recycled content, expanding both mechanical and chemical recycling infrastructure will help Europe to meet its sustainability goals. A 2018 report from ETH Zurich, in cooperation with CEFLEX, showed that to achieve the EU’s 55% recycling target, countries will need to increase sorting capacity for flexible packaging by a factor of 2.6 and recycling capacity by a factor of nearly five (4).

Chemical recycling of plastics can complement mechanical recycling because it creates a virgin-equivalent grade of recycled resin, allowing production of food grade flexible packaging (sometimes called "soft plastics").

Along with the buzz about chemical recycling we need to understand what the benefits and challenges around it are.

The difference between chemical and mechanical recycling

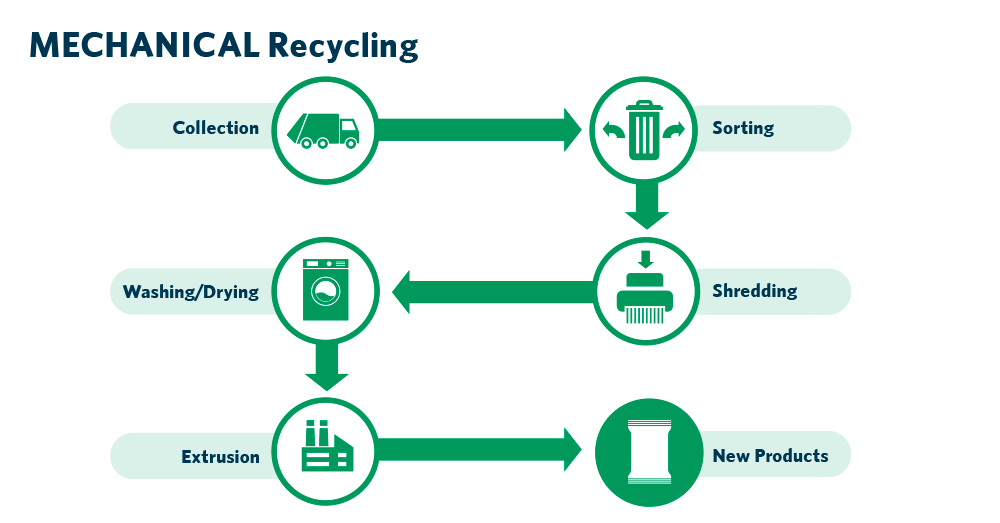

Mechanical recycling of plastics preserves the polymeric structure of the material. It involves different steps: sorting items according to their resin type, then shredding and eliminating impurities. Clean shredded material is then melted and extruded into post-consumer recycled plastics (PCR) resin pellets that can be used to make new products.

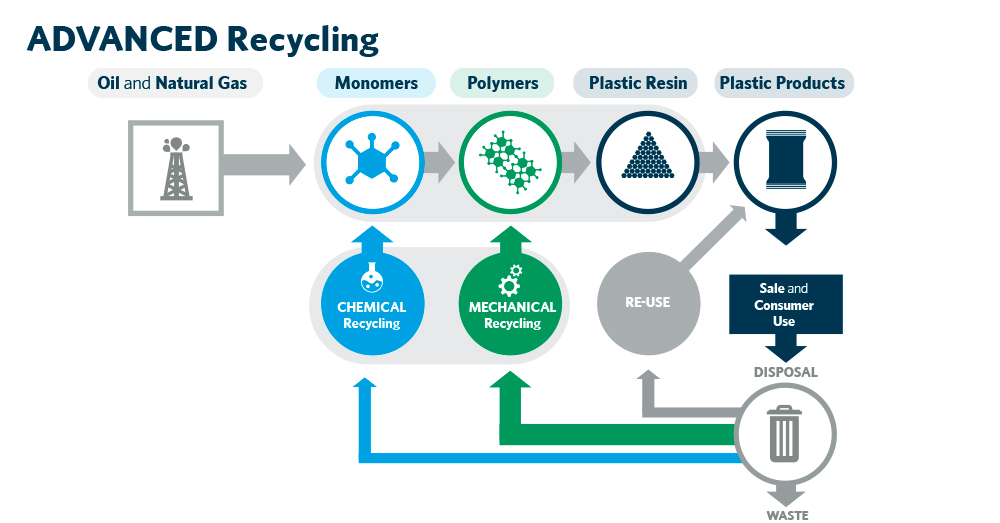

Chemical or advanced recycling, through different methods (chemical, thermal or catalytic processes), breaks down plastic material into its original building blocks. A chemical transformation breaks the links between monomers, which are the building blocks of polymers, which constitute plastics. The resulting resin pellets have the same purity and properties as virgin plastic resins.

Source: American Fuel and petrochemical Manufacturers

The benefits of chemical recycling

Chemically recycled resins can be used as a replacement for virgin quality resins, giving plastic waste a higher value. Thanks to its high quality, it can be used in specific applications such as flexible food-contact packaging, where mechanically recycled content has limitations today in Europe.

The Amcor AmPrima® portfolio of products is highly compatible with chemically recycled material. AmPrima® offers a range of mono-PE and mono-PP solutions that are recycle-ready and currently recyclable in many European countries. A percentage of chemically recycled PE or PP (rPE or rPP) can be used to make our AmPrima® solutions for food-grade applications.

Chemically recycled rPE is also suitable for healthcare packaging, such as the recycle-ready Amcor HealthCare™ SureForm Forming Films and the Amcor HealthCare™ High Shield Pharma Laminates.

How EPR schemes support achieving recycling targets

Extended Producer Responsibility (EPR) is a policy approach where producers contribute toward financial and operational responsibility for the collection, sorting, and treating of used packaging. The approach is not new, but has seen a surge in support from brands in the last few years, which is good news for building stronger recycling infrastructures for the future.

EPR can have a positive impact on packaging design because material that is easier to recycle carries a lower EPR fee, encouraging packaging innovation. The approach can of course apply to both mechanical and chemical recycling.

Does chemical recycling change how to design packaging for recyclability?

Finally, clear design-for-recycling guidelines for plastic packaging are still needed for chemical recycling. There is often a misconception that with chemical recycling it will be possible to throw anything in and get virgin quality resin back. In order for chemical recycling to be both economically viable and environmentally beneficial, the standards for input need to be high. According to Chemical Recycling Europe, improved eco-design is the first step in ensuring that both mechanical and chemical recycling can recycle the plastic item. (5)

Essentially, the same design-for-recycling rules that apply to materials designated for mechanical recycling must also be applied to materials designated for chemical recycling, so that packaging can go into either system and be recyclable.

Amcor continues to focus on R&D to create packaging that is easier to recycle – for both recycling pathways. In January 2018, Amcor pledged to design all our packaging to be recyclable or reusable and significantly increase our use of recycled materials by 2025. In 2023, already we had developed recycle-ready solutions for 89% of our flexible packaging portfolio, by square meter (sqm). And beyond our products, we also focus on partnerships that encourage the expansion of waste management infrastructure, and help empower consumers to recycle more.

Would you like to stay up to date on the latest industry trends? Sign up here to receive regular information, invitations to webinars about sustainability, regulations and other current packaging topics.

Brand owners have the most power to drive change by demanding sustainable packaging for their products. We can help you make the switch to more sustainable packaging solutions, click here to find out more.

References:

1- Source EEB European Environmental Bureau : Report “Recycling – who really leads the world?”

https://eeb.org/library/recycling-who-really-leads-the-world/

2- Source Plastics the facts 2020 by Plastics Europe

https://www.plasticseurope.org/application/files/8016/1125/2189/AF_Plastics_the_facts-WEB-2020-ING_FINAL.pdf

3- Source Eurostat, Packaging waste by waste management operations EU 27 Countries (from 2021), https://www.eea.europa.eu/data-and-maps/indicators/waste-recycling-2/assessment

4- Source Closing the loop for multilayer flexible packaging – barrier analysis, 31st December 2018 https://ethz.ch/content/dam/ethz/special-interest/mtec/sustainability-and-technology/PDFs/190318%20Ceflex%20Report%20_%20final.pdf

5- https://www.chemicalrecyclingeurope.eu/copy-of-about-chemical-recycling

Related Insights

More sustainable packaging: 5 common questions

December 5, 2024

Bust common sustainability myths, with the five most common questions our packaging sustainability experts hear. Gerald Rebitzer, Sustainability Director, shares his answers.

Bust common sustainability myths, with the five most common questions our packaging sustainability experts hear. Gerald Rebitzer, Sustainability Director, shares his answers.

Infographic: Unlock your brand's potential with recyclable retort packaging

June 24, 2022

While standard retort (heat treated) pouches are useful and popular, they're not recyclable - and that's a problem. Knowing it was one of the most difficult technical challenges in flexible packaging, why did the Amcor team try to solve it? Learn more about our award-winning AmLite HeatFlex™ recycle-ready innovation and what it means for heat-treated foods, in the infographic below.

While standard retort (heat treated) pouches are useful and popular, they're not recyclable - and that's a problem. Knowing it was one of the most difficult technical challenges in flexible packaging, why did the Amcor team try to solve it? Learn more about our award-winning AmLite HeatFlex™ recycle-ready innovation and what it means for heat-treated foods, in the infographic below.

5 things to know about the EU Packaging and Packaging Waste Regulation

March 16, 2023

Perhaps you’ve heard about the new European Union draft Packaging and Packaging Waste Regulation (PPWR). Maybe you even know a little about it. Yet, you might be wondering what it means for your business, your consumers, and the planet. Read on to learn more.

Perhaps you’ve heard about the new European Union draft Packaging and Packaging Waste Regulation (PPWR). Maybe you even know a little about it. Yet, you might be wondering what it means for your business, your consumers, and the planet. Read on to learn more.