Are Thermoformed Plastic Trays the Best Packaging Format for My Medical Devices?

Medical

November 9, 2022Reading time: 2 minutes

Medical device packaging is designed to address specific functionalities and regulations. Pouches, bags, forming films, laminations, die-cut lids, and thermoformed plastic trays are all common and viable packaging solutions.

Determining which format is right for a particular application isn’t always clear-cut, yet oftentimes medical device designers opt for thermoformed plastic packaging from a project’s outset. The decision isn’t arbitrary, which may have you wondering what they know about thermoformed trays that could also serve your application.

Could thermoformed plastic trays be the best choice for your medical device packaging? Amcor’s healthcare packaging experts are invaluable when it comes to answering this question with specificity, but learning about the general advantages of this packaging format will help you make some initial decisions.

Appropriate applications for thermoformed plastic packaging

The medical industry is vast, as are the number and types of medical devices in use within the various sectors.

The needs and characteristics of medical devices drive packaging choice, design, and manufacture. Swabs or other commodity items, for example, may be better suited for a pouch versus a tray. Likewise, there are certain applications that warrant thermoformed trays, such as:

- Orthopedic devices (e.g., artificial joints) that aid in restoring skeletal systems

- Minimally invasive devices (e.g., cameras, sensors, robotics, instruments) that make it possible for operations to be performed without major incisions

- Electro-mechanical devices (e.g., cardiac defibrillators and pacemakers, ventilators) that use electrical pulses to create a mechanical movement that precisely controls motion

- Procedure kits that package one or more medical devices together for use in a single medical procedure (e.g., trauma or joint replacement/repair)

- Catheters, guidewires, and stents used in cardiovascular procedures (e.g., angioplasty) and select other medical events

- Injection systems (e.g., syringes, needles) that facilitate the delivery of drugs, vaccines, and biopharmaceuticals

While not an exhaustive list, these examples represent applications that ideally align with the advantages of thermoformed trays.

6 benefits of thermoformed trays

- Sterile barrier protection: Medical device sterilization is of utmost importance. Even subtle device movement within packaging could compromise sterile barriers. Devices can be snapped into thermoformed trays so they are immobilized until physically removed.

- Confident handling: Thermoforming machines create trays that snugly nest medical devices, enabling healthcare professionals to control the device in order to preserve sterile barriers, prevent unnecessary rotation, and ensure devices don’t accidentally deploy.

- Package clarity: Being able to see the device through the packaging allows healthcare professionals to quickly verify that the medical device is correct, defect-free, and well-positioned for presentation at the point of use.

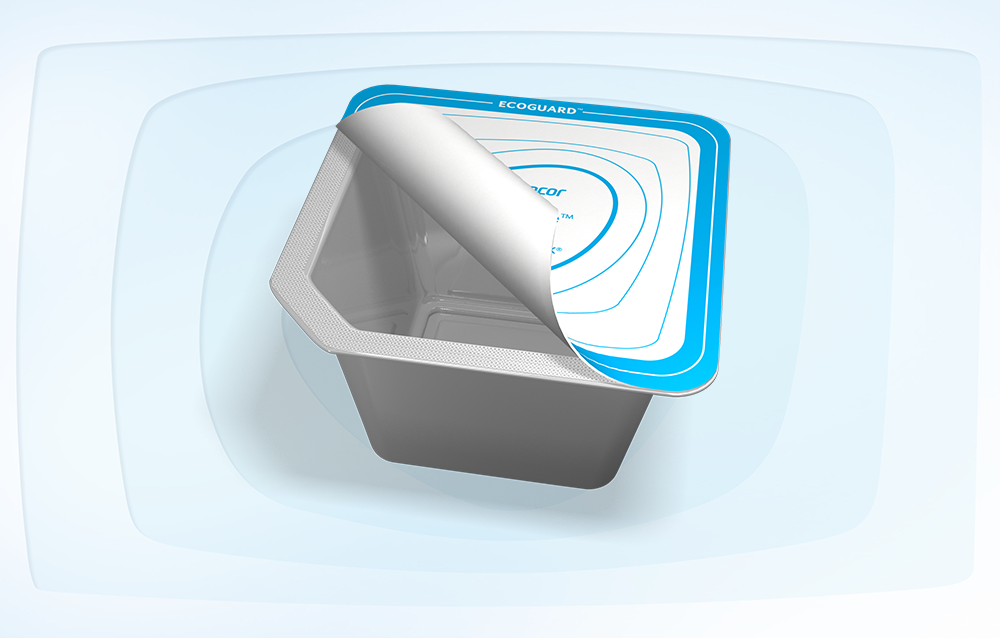

- Controlled opening: Thermoformed packaging hermetically bonds the rigid tray material and flexible lidding material, resulting in a strong seal that resists sterile barrier contamination, damage, and opening during transport, handling, and storage. However, that same package needs to open easily at the point of use. Thermoformed trays are designed with peel systems that have large peel areas that can be effortlessly opened without prematurely breaking the sterile barrier, and provide easy access to the device.

- Design versatility: A full range of material options are available for trays (HDPE, PP, PETG, HIPS, APET) and lidding (Tyvek, papers, foils, some polymers) which support design innovation and the thermoforming process from concept through commercialization.

- Right-sized packaging: Thermoformed parts create packaging tailored to fit medical devices. Since less packaging material is required, there is less waste — which translates to eco-friendliness and cost effectiveness.

With so many benefits, a strong case can be made for using thermoformed plastic trays for your medical devices. However, before you commit to a packaging format, weigh the importance of sterile barrier protection throughout distribution, handling, storage, and end-use.

It’s a key consideration for medical devices, and you’ll find valuable information in our Insider’s Guide to Sterile Barrier Packaging. Click the button below to download your copy now.